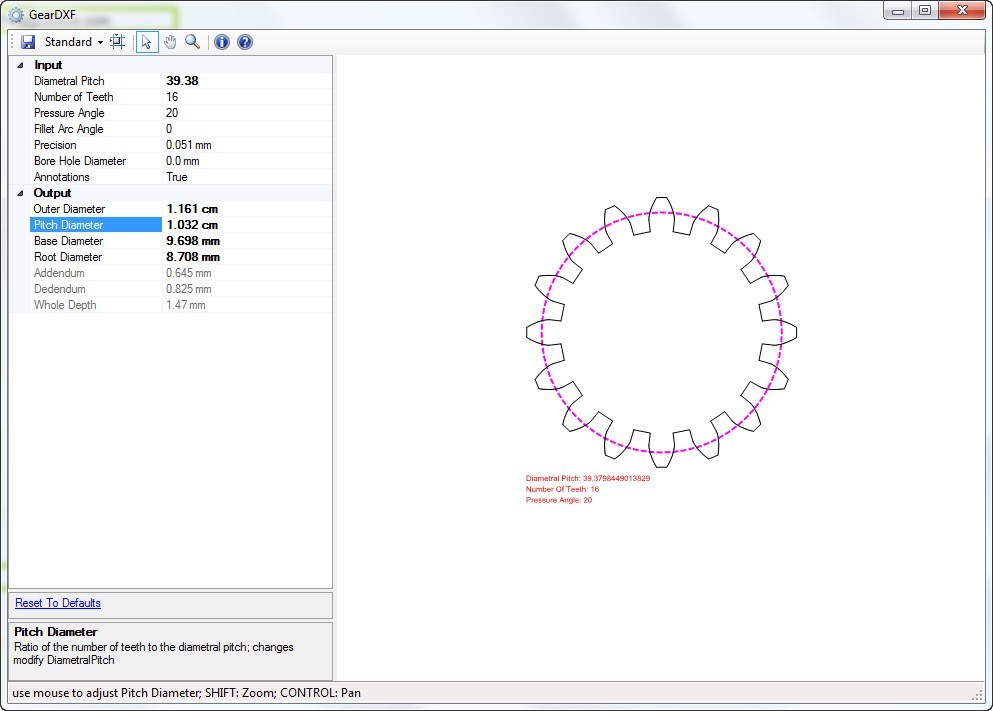

Hello, I've made the gear as you said (m=2.3mm | z=24 | ha = 14deg) and found that it´s accurately designed. This design method is still in development and should not be relied on for accurate visualization or industrial level designing. If you’re planning to fabricate these gears using our designs, you have to consider they won’t reflect the “under cut” condition (for more information, visit KHK Profile Shifting). Profile shifting is a manufacturing method for gears that are needed to fit a larger/smaller mesh space while remaining with the same specs (number of teeth, module, pressure angle, etc.). The two variants considered experimental are the ones that use profile shifting.

Nonetheless, these designs are as useful as others. The two types considered non-standard were included for 3D printing since these designs of internal gears have proven to be practical when tight tolerances are a liability.

0 kommentar(er)

0 kommentar(er)